When choosing a solar power plant, individuals and businesses pay the most attention to its power – after all, this will determine how much electricity will be produced. Other equipment, systems and sensors that allow monitoring and analysis of the operation of the power plant are often underestimated. But they shouldn’t be: the solar power plant will be used for several decades, so various failures and poor-quality monitoring can have a significant impact on the efficiency of electricity

The efficiency of a solar power plant is affected by many factors, from dust, dirt, pollen, and shadows cast by trees, to the failure of various parts, connectors and cables. To ensure the best return on investment, it is important to accurately identify problems and eliminate them on time. All of this is taken care of by the monitoring equipment of the solar power plant, except for physical repairs and equipment replacement.

Manufacturers’ promises and reality differ

The PV inverters of some manufacturers have integrated monitoring solutions that allow you to see the amount of electricity produced or several other parameters. However, those who know the specifics of solar power plants understand very well that this is just a drop in the ocean. Knowing only one or a few parameters makes it impossible to fully assess the power plant’s efficiency, to notice the nuances that influence it, and to anticipate possible breakdowns or energy loss due to neglect.

Standard monitoring tools monitor several parameters related to the energy and power produced by the solar plant. This data is usually updated once every 15 minutes. To better understand how the solar power plant works, our team of scientists has developed a monitoring tool that captures an average of 25 parameters, and the data is updated every 10 seconds. Ten times more data allows supervisors to ensure extremely accurate monitoring and react to problems in real time.

Our internal data shows that solar plants rarely reach their declared maximum capacity. This is because they are tested and their maximum power is determined under laboratory conditions that are rarely achieved in reality. Inion Software’s experience shows that the attitude of the manufacturers has a great influence: in many cases, the documentation of cheap equipment produced outside European Union (EU) indicates the maximum power that can be achieved under ideal conditions, while EU manufacturers calculate the minimum amount of electricity their power plants will produce under ideal conditions. In other words, it is practically impossible to see the figures declared by the cheap producers in reality, while EU-made power plants can achieve even higher production.

Even small things can have a big impact

However, the efficiency of even two identical solar power plants installed in different locations can differ significantly. Not only due to cloudiness, seasonality, direction or angle of the roof, but also for many other reasons.

Our research shows that if even a small area of the solar panel is covered, for example, by falling leaves, dirt, or the shadow of a tree or bush – the overall efficiency of the power plant is significantly reduced. In some cases, even a tenth of the covered area can reduce total production by up to 30%. Therefore, periodic cleaning of solar modules, pruning of surrounding vegetation and similar maintenance play a crucial role.

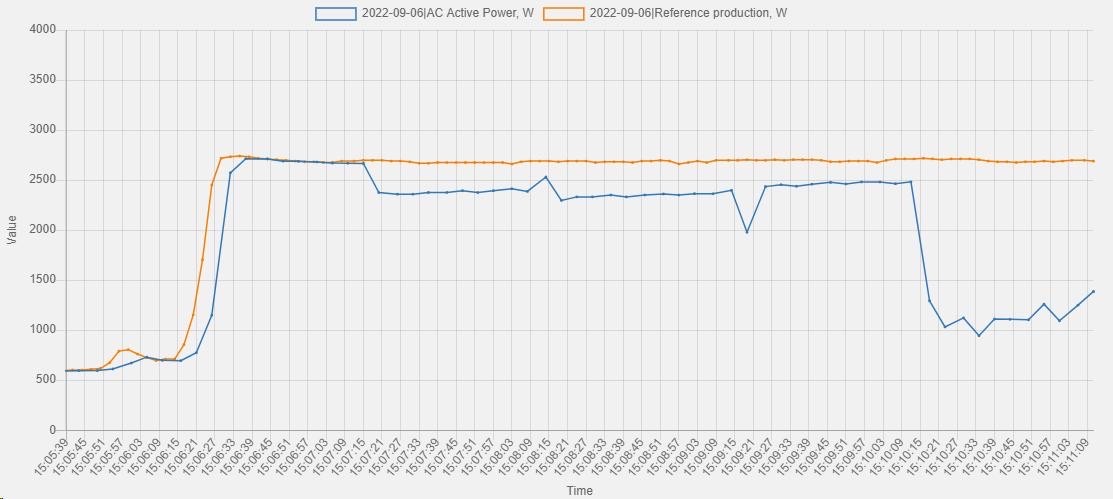

The infographic below shows how the power plant’s efficiency is reduced if leaves fall on one of the panels:

Not all problems are noticed and solved so simply. Solar power plants are full of equipment, connectors, and other components that can fail or disconnect unexpectedly. As a result, electricity production can be reduced or even completely stopped. There are many different examples. The information we have gathered shows that a common problem with solar power plants is inventories heating up. They are usually housed in closed cabinets that protect them from rain, snow, and other environmental factors, but this poses a risk of overheating.

Even the smallest nuances, such as poorly sealed connections, can cause problems. Moisture entering through them can interfere with proper operation. For example, inverters affected by morning dew may measure the isolation resistance incorrectly and fail to start on time. An average solar park can lose thousands of euros in revenue per year due to such a failure.

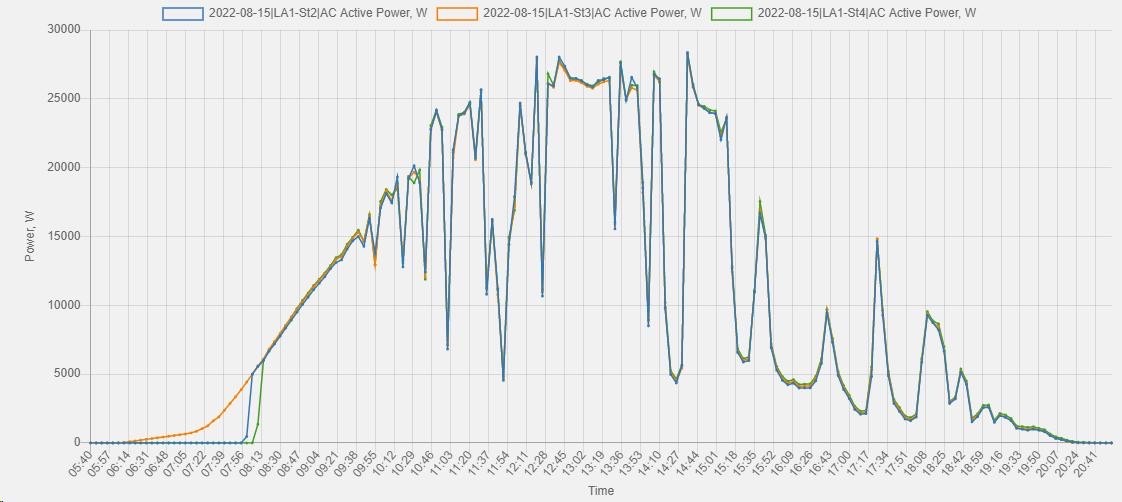

The second infographic shows how the three solar power plants work. Due to poorly sealed connections two fail to start on time:

The quality of monitoring is particularly important

There are things that simply cannot be fixed or improved – it is natural that solar plants will generate less electricity on cloudy days and in winter, and their efficiency decreases due to wear and tear. The latter factor usually determines a slight, up to 0.5% degradation, decrease in production per year. In other words, if your solar farm produced 10,000 kWh of electricity in the first year, it should still produce about 9,950 kWh in the second year. These are only theoretical calculations, since identical weather conditions do not occur every year. However, in order to distinguish normal fluctuations from anomalies, a high-quality and reliable monitoring system is necessary.

Popular content

Aptera’s solar car to use Maxeon PV cells6 OCTOBER 2022Aptera’s solar electric vehicle, equipped with almost 700 W of PV cells, can drive up to 40 miles (64 km) on solar alone, or 1,000 miles on batteries…How long do residential energy storage batteries last?4 OCTOBER 2022Multiple factors can affect the lifespans of residential battery energy storage systems. October 4, 2022 Ryan Kennedy Distributed Storage Energy S…New solar tiles from Germany6 OCTOBER 2022Creaton and Autarq have developed a modular solar tile for complex rooftops. The product is reportedly compatible with all common PV inverters. Octo…New study shows impact of shading on PV cells30 SEPTEMBER 2022Scientists in China have studied the impact of shading on single solar cells and on simple arrangements of two cells connected in series or in parall…Dutch startup stabilizes Dutch grid with 9 MWh battery-flywheel storage facility4 OCTOBER 2022S4 Energy and ABB recently installed a hybrid battery-flywheel storage facility in the Netherlands. The project features a 10 MW battery system and a…EU member states could use emergency energy measures to penalize solar5 OCTOBER 2022SolarPower Europe has called on EU nations to apply a blanket €0.18 ($0.18)/kWh cap on the revenue generated by low-margin power plants, even though…Aptera’s solar car to use Maxeon PV cells6 OCTOBER 2022Aptera’s solar electric vehicle, equipped with almost 700 W of PV cells, can drive up to 40 miles (64 km) on solar alone, or 1,000 miles on batteries…How long do residential energy storage batteries last?4 OCTOBER 2022Multiple factors can affect the lifespans of residential battery energy storage systems. October 4, 2022 Ryan Kennedy Distributed Storage Energy S…New solar tiles from Germany6 OCTOBER 2022Creaton and Autarq have developed a modular solar tile for complex rooftops. The product is reportedly compatible with all common PV inverters. Octo…New study shows impact of shading on PV cells30 SEPTEMBER 2022Scientists in China have studied the impact of shading on single solar cells and on simple arrangements of two cells connected in series or in parall…Dutch startup stabilizes Dutch grid with 9 MWh battery-flywheel storage facility4 OCTOBER 2022S4 Energy and ABB recently installed a hybrid battery-flywheel storage facility in the Netherlands. The project features a 10 MW battery system and a…EU member states could use emergency energy measures to penalize solar5 OCTOBER 2022SolarPower Europe has called on EU nations to apply a blanket €0.18 ($0.18)/kWh cap on the revenue generated by low-margin power plants, even though…Aptera’s solar car to use Maxeon PV cells6 OCTOBER 2022Aptera’s solar electric vehicle, equipped with almost 700 W of PV cells, can drive up to 40 miles (64 km) on solar alone, or 1,000 miles on batteries…

- 1

- 2

- 3

- 4

- 5

- 6

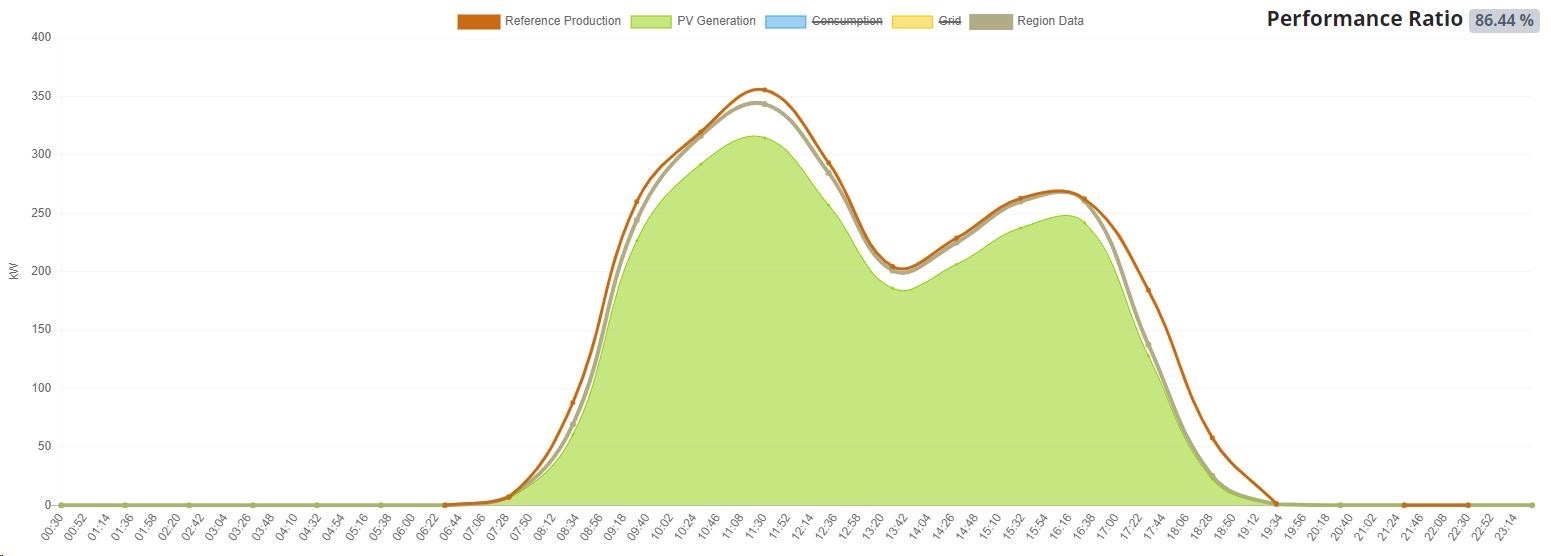

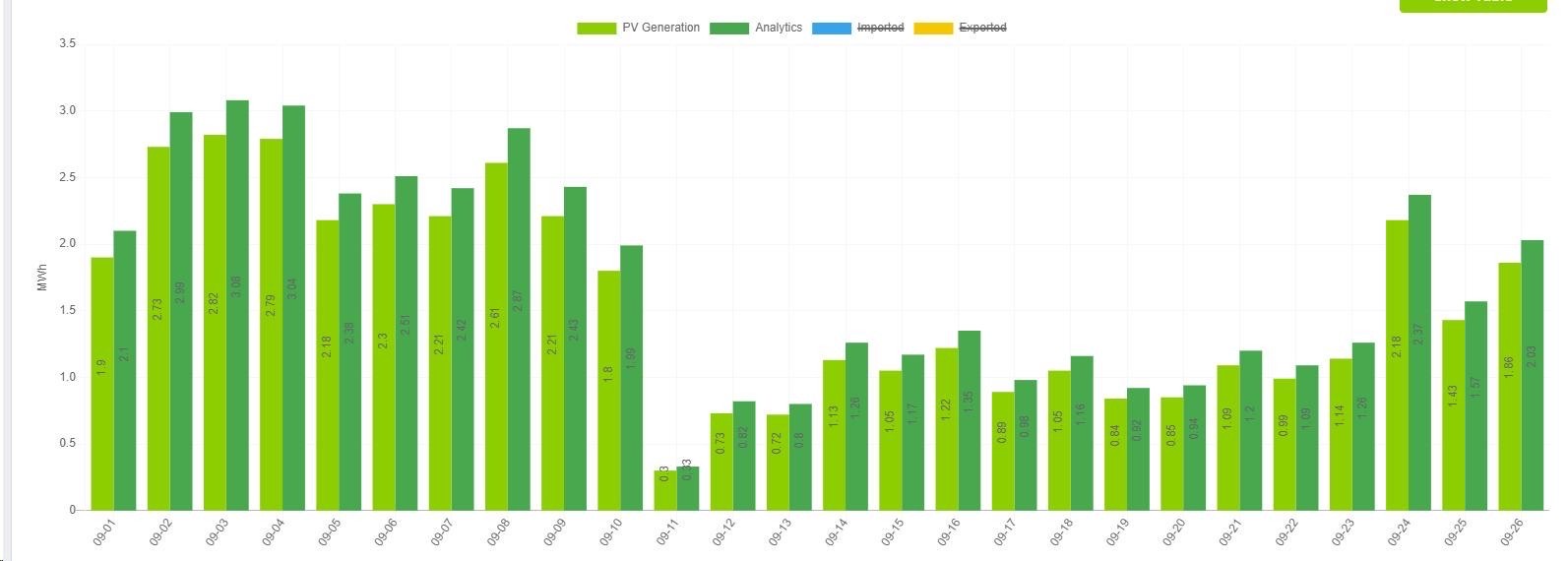

It is common in the market that the operating capacity of a solar power plant is calculated thanks to a solar radiation sensor. It shows whether the solar plant is producing electricity as much as the weather conditions permit. However, this sensor cannot always accurately reflect the real weather conditions, because it often doesn’t work at full capacity due to dust and dirt. As a result, solar farm owners cannot always see if electricity is being produced efficiently. To see more precisely the operation of the power plant, our team of scientists has developed a unique monitoring system that does not require a solar radiation sensor. The efficiency of the solar power plant is compared to the work of nearby power plants.

For example, if on sunny days one solar plant produces less electricity than other plants in the same region, this is a signal that the plant is not operating at full capacity.

The following infographics showing the capacity of a power plant when measured with a solar radiation sensor and measured by taking an average in the region (Red indicates the reference production measured with a solar radiation sensor, while green shows PV generation).

Solar power plants are entering a new stage, when the rapidly improving monitoring equipment will allow the power plant to produce electricity more efficiently.

About the author

Dr. Robertas Janickas is the CTO at Inion Software. He has over 10 years of experience in management, software, SW & HW development. Inion Software is a company developing a solar power plant monitoring platform and energy management system for battery management in one place.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.